Are you considering Hardie Board fiber cement siding for your home remodeling or addition? Fiber cement is an eco friendly product that is also energy efficient. You may even qualify for a new siding rebates and incentives, check if you are eligible here and here.

Fiber cement cladding is a popular and durable option can protect your home from the elements while providing a sleek, modern appearance and avoid costly repairs when done properly. This siding mimics the look of real wood without the hassle of the maintenance.

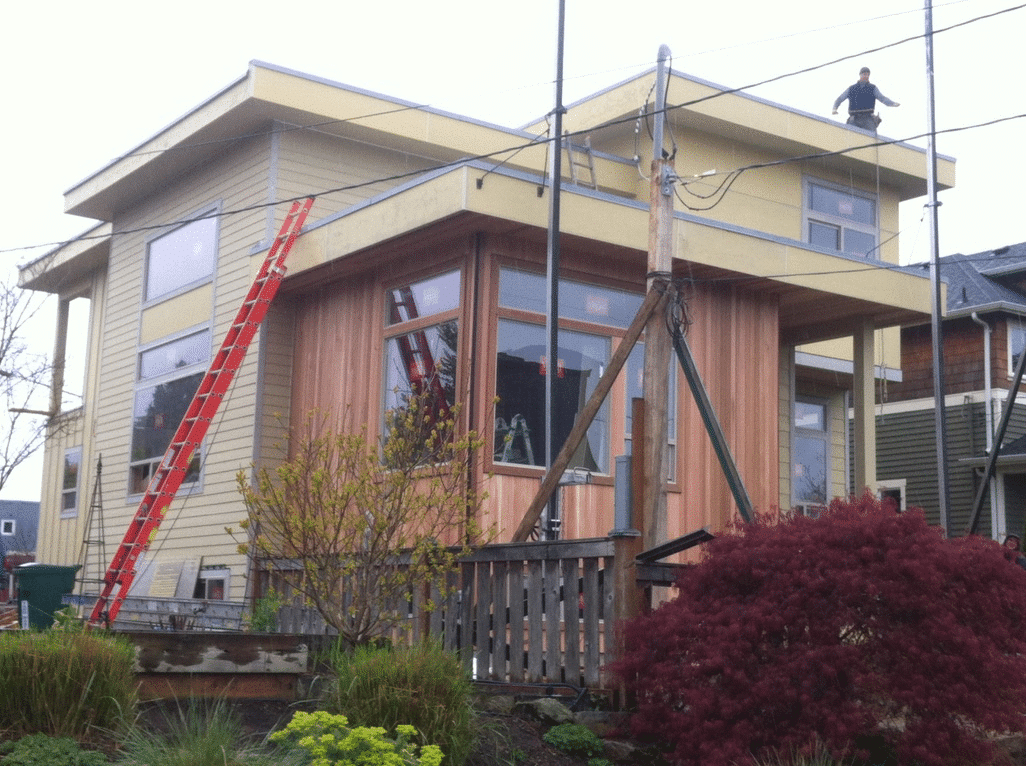

But how do you go about installing it yourself? In this comprehensive guide, we will walk you through the process of how to install Hardie Board siding 4×8, including necessary tools and materials, preparation, cutting, and installation techniques to achieve a professional finish. Let’s get started on transforming your home’s exterior with the guidance of your professional, licensed, and registered Seattle siding contractor!

Short Summary

Prepare your tools and materials for Hardie Board siding installation.

Follow James Hardie’s instructions to ensure a successful project.

Measure, cut, and fasten panels correctly for a professional finish.

Preparing for Hardie Board Siding Installation

Before diving into the Hardie siding installation, it is crucial to prepare adequately to ensure a successful project. Proper planning and gathering the right tools and materials can make all the difference in the final outcome.

Since Hardie Board is a fiber cement product from James Hardie, it is essential to understand and follow the manufacturer’s installation instructions to avoid common issues that homeowners might face with Hardie Plank.

Necessary Tools and Materials

To install Hardie Board fiber cement siding panels, you will need specific tools such as:

16-gauge finish nail gun

Circular saw

PacTool SA903 Gecko Gauge Siding Mounting Kit

Fiber cement shears & attachments

Plank & trim cutters

Miters and saws

Fiber cement blades

Hand snips and shears

Fiber cement notchers

Nail cutters

These tools will help you achieve precise cuts and secure the panels to the wall.

The materials required for the project include:

Hardie Board panels

House wrap

Nails or screws

Permanently flexible sealant or caulk, as recommended by James Hardie, to seal the joints and prevent moisture infiltration.

Understanding Installation Instructions

Adhering to James Hardie’s installation guidelines is critical for achieving a successful project. These instructions can be found on the James Hardie Pros website, offering comprehensive guidance on how to install Hardie Board siding, as well as care and maintenance information. Not only will following these guidelines ensure a durable and long-lasting installation, but it will also help you avoid common pitfalls that can occur during the process.

By familiarizing yourself with the proper installation techniques and understanding the rationale behind them, you can feel confident in your ability to tackle this DIY project and achieve a professional-looking result.

Installing House Wrap and Preparing the Wall

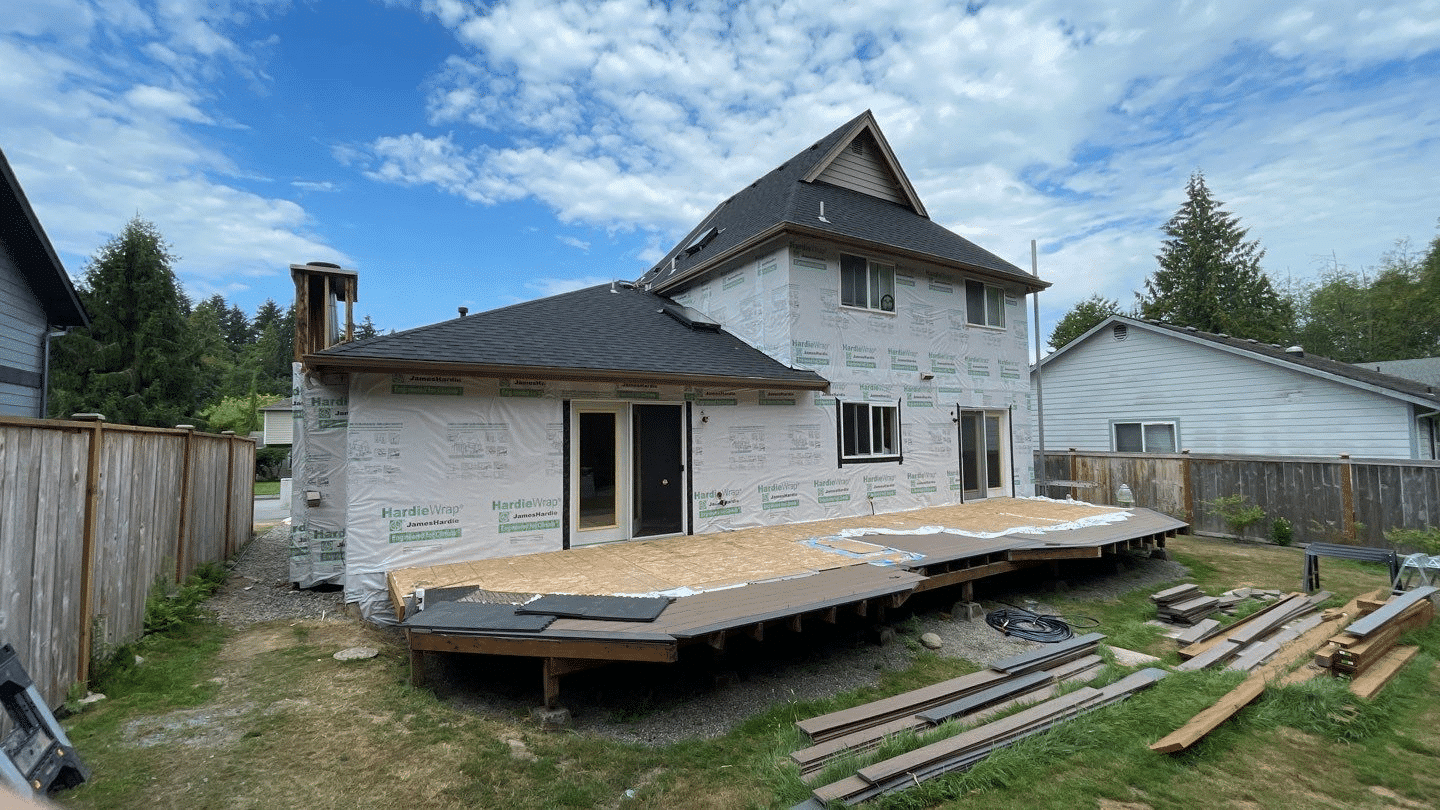

Before installing the actual Hardie Board siding panels, it is crucial to prepare the wall surface to avoid any problems from developing, such as moisture and mold. Installing house wrap is a vital step in protecting your home from moisture and other elements.

In addition, preparing the wall surface by ensuring it is clean, flat, and dry is essential for a successful installation.

House Wrap Installation

To properly install house wrap for humid Seattle weather, follow these steps:

Measure the wall area and cut the wrap to size with a utility knife.

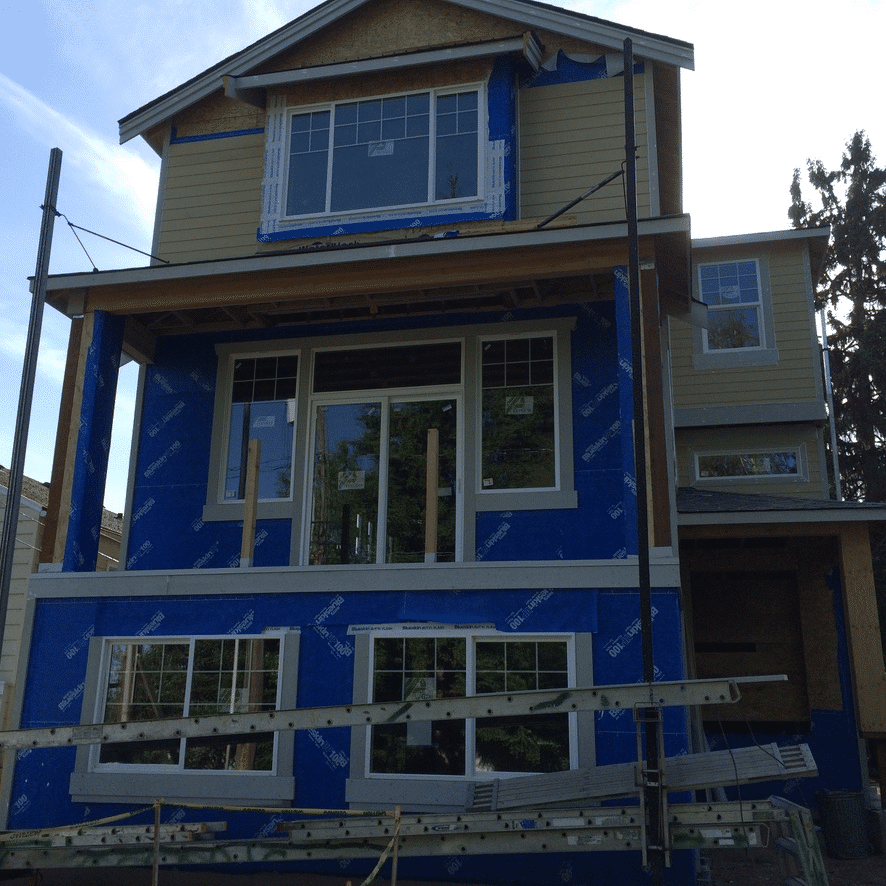

Apply the house wrap to sheathed walls made of foam, plywood, or oriented strand board (OSB), ensuring it is secure and free from wrinkles or tears.

Fasten the house wrap to the wall using staples or nails, making sure there are no gaps or wrinkles.

Keep in mind the suggested minimum distance between the paneling and a wood decking or concrete pad (1 inch) and the paneling’s bottom and the ground (6 inches).

Wall Surface Preparation

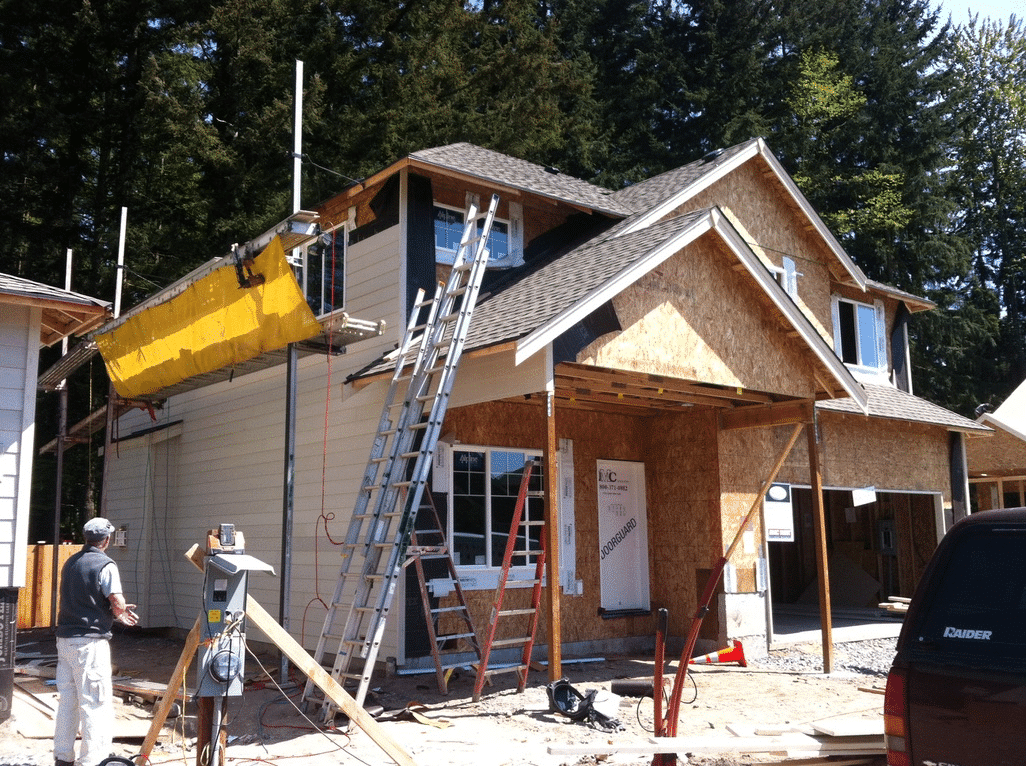

Once the house wrap is in place, it’s time to prepare the wall surface for the Hardie Board siding installation. Recommended sheathing materials include plywood or OSB. Ensure the wall is clean, flat, and dry, as this will significantly impact the siding’s final appearance and performance.

Next, secure the Hardie Board using galvanized or stainless siding nails, placing them 1 inch below the top edge at each stud, with a maximum spacing of 16 inches apart. Proper panel alignment is essential to avoid gaps and ensure a visually appealing result.

Measuring and Cutting Hardie Board Panels

After preparing the wall surface, the next step is to measure and cut the Hardie Board siding panels accurately. Precise measurements and cuts are essential to achieving a professional finish and preventing issues such as cracking and breaking.

It is important to take the time to measure and cut the panels correctly. Measure twice.

Measuring Techniques

To measure the wall area and calculate the number of panels needed, start by measuring all doors, windows, and other exterior areas that do not require siding. Subtract this figure from the total area of the wall to obtain the total area for the panels.

This method ensures that you have the correct number of panels for your project and minimizes waste.

Cutting Panels

When cutting the Hardie Board panels, use a carbide-tipped scoring knife or a circular saw with a blade specifically designed for cutting fiber cement. These tools allow for precise cuts without damaging the panels. When using a scoring knife, score the panel along the desired cut line and then break the panel along the scored line.

For a circular saw, use a blade specifically designed for cutting fiber cement.

Installing Hardie Board Siding Panels

With the panels measured and cut, it’s time to install the Hardie Board siding, including the Hardie Panel. This section will walk you through a step-by-step guide on installing the panels, ensuring a professional and long-lasting result.

Start by prepping the area. Make sure the surface is clean and free of debris.

Starting at the Base

Begin the installation at the base of the wall, aligning the bottom of the panels with a marked level line. This ensures that the panels are level and properly aligned, contributing to a visually appealing and secure installation.

When installing the panels, be mindful of the recommended distance between the corner trim and siding (18 inches).

Fastening Panels

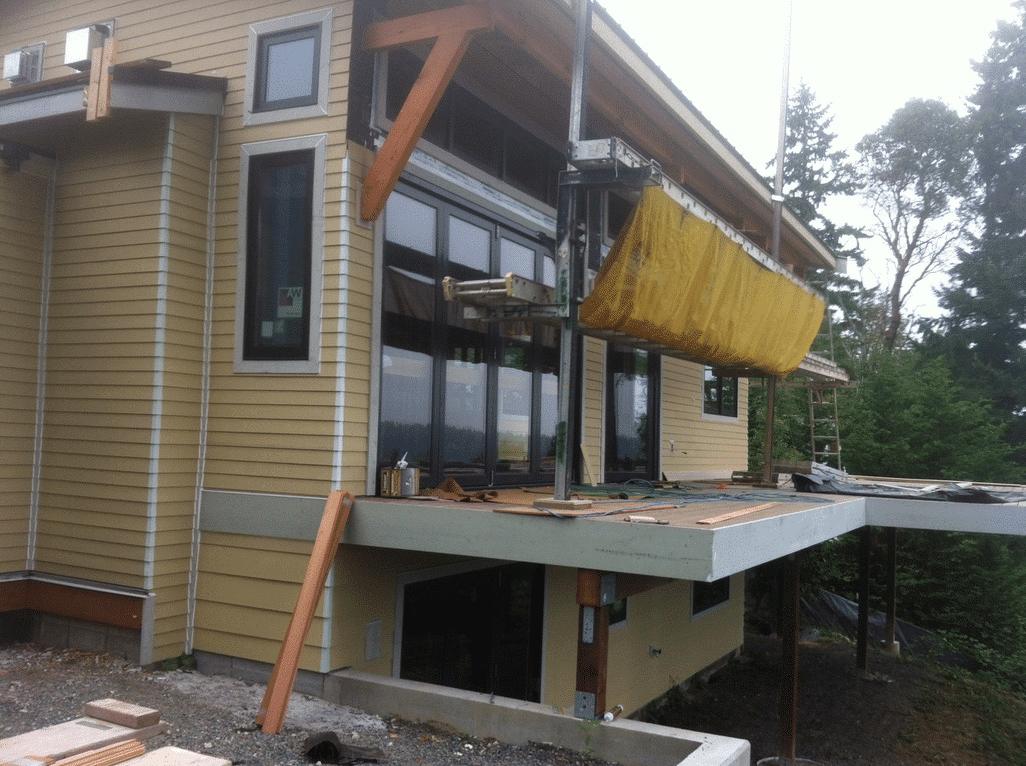

Next, fasten the panels using z metal galvanized or stainless steel screws or nails, overlapping a stud. Pre-drill the holes and use corrosion-resistant fasteners to ensure a secure and long-lasting installation. Fasteners should be positioned no closer to the edges of the panels than 3/8 inch, maintaining proper spacing to prevent damage and ensure a visually appealing result.

To ensure the best results, use the appropriate fasteners for the material you are working with.

Managing Vertical and Horizontal Joints

When handling vertical and horizontal joints, such as butt joints, Z flashing, and H-flashing, it is crucial to follow the proper techniques for a successful installation. Here are some tips:

Install Z flashing above doors and windows to ensure waterproofing.

Stagger butt joints to maintain a visually appealing appearance.

Use wood or fiber cement battens to cover joints, or install H-flashing to conceal them.

Working Around Doors and Windows

Properly installing Hardie Board siding around doors and windows is essential to ensure waterproofing and a professional finish. In this section, we will discuss the necessary steps to achieve a successful installation around these areas.

First, measure the area around the door or window to determine the amount of siding needed.

Installing Z Flashing

To install Z flashing above doors and windows, follow these steps:

Measure and cut the flashing to the appropriate length.

Secure the flashing to the sheathing above the shim.

This process ensures effective waterproofing and prevents moisture infiltration around these critical areas of your home.

Properly installed flashing is essential for protecting your home from water damage. It helps to keep the pace.

Trimming and Fitting Panels

When cutting and fitting panels around doors and windows, maintain a consistent gap for expansion and contraction. This helps prevent issues such as cracking and breaking of the Hardie Board siding.

Utilize trim blocks for retro-fitting around existing vents, and use siding nails to secure the panels in place.

Troubleshooting Common Installation Issues

Even with careful planning and execution, common installation issues may arise during the Hardie Board siding process. In this section, we will address these issues and provide solutions to help you achieve a successful project.

From improper cutting to incorrect nailing, there are a few common mistakes that can lead to problems.

Avoiding Cracks and Breaks

To minimize the risk of cracks and breaks in your Hardie Board siding, ensure accurate measurements, proper cutting techniques, and appropriate fastening methods.

Additionally, to ensure a visually appealing and long-lasting installation, it is important to:

Use the correct fasteners and follow the manufacturer’s instructions for installation.

Properly prepare the surface before installing the siding.

Maintain proper panel alignment to avoid gaps that can lead to cracking and breaking of the siding.

By following these guidelines, you can prevent common issues and ensure a visually appealing and long-lasting installation.

Proper Panel Alignment

Ensuring proper panel alignment is vital for a visually appealing result. Utilize alignment grooves on LP SmartSide Panel Siding to guarantee proper spacing between panels.

Take care to align the vertical panel grooves at the junctures between the first and second stories or gables for a polished and professional finish.

Seattle Siding Contractor KV construction Conclusion

In conclusion, installing Hardie Board siding 4×8 can be a rewarding DIY project that significantly enhances your home’s exterior appearance and protection. By following the guidelines and tips provided in this guide, you can successfully install Hardie Board siding with a professional finish. Remember to plan, gather the necessary tools and materials, and follow James Hardie’s installation instructions to ensure the best possible outcome for your home improvement project.

Frequently Asked Questions

Do you nail or screw Hardie siding?

For Hardie siding, it’s recommended to use nails for installation. You can either nail by hand or use a pneumatic nailer; however, the best option is a pneumatic nailer for speed and consistency.

Face nails should be used at the bottom and blind nails should be used at the top.

Can Hardie board be attached directly to studs?

Yes, HardiePanel® and HardiePlank® siding and trim products can be directly attached to studs or OSB sheathing of at least 7/16” thickness.

They can also be installed over solid-foam insulation board up to 1 inch thick.

What is the gap between Hardie board siding?

Hardie siding requires a 1/8” gap with the trim and 3/8” bead of approved caulking to protect and seal the edge.

What tools are needed for Hardie Board siding installation?

For successful Hardie Board siding installation, you need a circular saw, fiber cement shears, finish nail gun, and PacTool SA903 Gecko Gauge Siding Mounting Kit.

How do I properly install house wrap?

Secure house wrap to the sheathed walls using staples or nails, ensuring a wrinkle- and gap-free installation. Measure and cut it to fit the wall area beforehand.